Transair® Aluminum Lockout Valves

Diameter: 1/2"(16.5mm)

Transair's Pneumatic Lock-out valves provide a safe, OSHA approved solution for rapid machine shut-off. OSHA requires the use of a lock-out valve near the point of use. Lockout valves are installed in pneumatic drop legs, or individual pneumatic control lines. Lockout valves are used during maintenance and service procedures of pneumatically (air) operated equipment. FLV8NAB 1" IN STOCK.

➤ Click Here for Technical DataNote: California residents click here for Proposition 65 information

WARNING:

These products described herein can expose you to chemicals known to the State of California to cause cancer or reproductive harm.

For more information go to www.p65Warnings.ca.gov

■ Used for compliance with OSHA 29 CFR part 1910*

■ Cast aluminum body

■ Inline or surface mountable

■ Built in port for pressure verification to meet ANSI B11 and PMMI B155 requirements

■ Teflon seals outperform competitor models using Buna-N

■ Cast aluminum body

■ Inline or surface mountable

■ Built in port for pressure verification to meet ANSI B11 and PMMI B155 requirements

■ Teflon seals outperform competitor models using Buna-N

TransairPipeSales.com is your complete source for Transair 1/2" Lockout valves. Transair® 1/2" Lockout valves are quick and easy to install.

*The 1910.147 OSHA standard requires control of the release of stored energy via lockout or via tagout where the energy isolating device is not capable of being locked out.

*The 1910.147 OSHA standard requires control of the release of stored energy via lockout or via tagout where the energy isolating device is not capable of being locked out.

Standard Models & Dimensions

Lockout Valves - 1/2 in

Product #: FLV4N6B

PORT IN/OUT(in): 1/2

PORT EXH(in): 3/4

A (in): 8.32

A1 (in): 0.64

B (in): 6.60

C (in): 2.00

D (in): 3.06

E (in): 4.24

F (in): 1.32

G (in): 1.56

H (in): 2.21

PORT IN/OUT(in): 1/2

PORT EXH(in): 3/4

A (in): 8.32

A1 (in): 0.64

B (in): 6.60

C (in): 2.00

D (in): 3.06

E (in): 4.24

F (in): 1.32

G (in): 1.56

H (in): 2.21

Lockout Valves - 3/4 in

Product #: FLV6N6B

PORT IN/OUT(in): 3/4

PORT EXH(in): 3/4

A (in): 8.32

A1 (in): 0.64

B (in): 6.60

C (in): 2.00

D (in): 3.06

E (in): 4.24

F (in): 1.32

G (in): 1.56

H (in): 2.21

PORT IN/OUT(in): 3/4

PORT EXH(in): 3/4

A (in): 8.32

A1 (in): 0.64

B (in): 6.60

C (in): 2.00

D (in): 3.06

E (in): 4.24

F (in): 1.32

G (in): 1.56

H (in): 2.21

Product #: FLV6NAB

PORT IN/OUT(in): 3/4

PORT EXH(in): 1-1/4

A (in): 9.91

A1 (in): 0.85

B (in): 7.95

C (in): 2.25

D (in): 3.91

E (in): 5.65

F (in): 1.74

G (in): 1.89

H (in): 2.74

PORT IN/OUT(in): 3/4

PORT EXH(in): 1-1/4

A (in): 9.91

A1 (in): 0.85

B (in): 7.95

C (in): 2.25

D (in): 3.91

E (in): 5.65

F (in): 1.74

G (in): 1.89

H (in): 2.74

Lockout Valves - 1 in

Product #: FLV8NAB

PORT IN/OUT(in): 1

PORT EXH(in): 1-1/4

A (in): 9.91

A1 (in): 0.85

B (in): 7.95

C (in): 2.25

D (in): 3.91

E (in): 5.65

F (in): 1.74

G (in): 1.89

H (in): 2.74

PORT IN/OUT(in): 1

PORT EXH(in): 1-1/4

A (in): 9.91

A1 (in): 0.85

B (in): 7.95

C (in): 2.25

D (in): 3.91

E (in): 5.65

F (in): 1.74

G (in): 1.89

H (in): 2.74

High Flow Models & Dimensions

Lockout Valves - 1 1/2 in

Product #: FLVBNCB

PORT IN/OUT(in): 1-1/2

PORT EXH(in): 2

A (in): 14.82

A1 (in): 1.87

B (in): 8.2

C (in): 3.00

D (in): 5.89

E (in): 1.5

F (in): 5.81

G (in): 2.43

G1 (in): 4.10

H (in): 4.34

J (in): 7.49

PORT IN/OUT(in): 1-1/2

PORT EXH(in): 2

A (in): 14.82

A1 (in): 1.87

B (in): 8.2

C (in): 3.00

D (in): 5.89

E (in): 1.5

F (in): 5.81

G (in): 2.43

G1 (in): 4.10

H (in): 4.34

J (in): 7.49

Lockout Valves - 2 in

Product #: FLVCNCB

PORT IN/OUT(in): 2

PORT EXH(in): 2

A (in): 14.82

A1 (in): 1.87

B (in): 8.2

C (in): 3.00

D (in): 5.89

E (in): 1.5

F (in): 5.81

G (in): 2.43

G1 (in): 4.10

H (in): 4.34

J (in): 7.49

PORT IN/OUT(in): 2

PORT EXH(in): 2

A (in): 14.82

A1 (in): 1.87

B (in): 8.2

C (in): 3.00

D (in): 5.89

E (in): 1.5

F (in): 5.81

G (in): 2.43

G1 (in): 4.10

H (in): 4.34

J (in): 7.49

ES Silencers High Flow

Product #: FES75MC

Pipe Size (in): 3/4

Flow (SCFM): 893

HEX (in): 1.62

Length (in): 4.56

Pipe Size (in): 3/4

Flow (SCFM): 893

HEX (in): 1.62

Length (in): 4.56

Product #: FES125MC

Pipe Size (in): 1-1/4

Flow (SCFM): 1486

HEX (in): --

Length (in): 5.69

Pipe Size (in): 1-1/4

Flow (SCFM): 1486

HEX (in): --

Length (in): 5.69

Product #: FES200MC

Pipe Size (in): 2

Flow (SCFM): 1580

HEX (in): 2.99

Length (in): 7.68

Pipe Size (in): 2

Flow (SCFM): 1580

HEX (in): 2.99

Length (in): 7.68

Pop-Up Pressure Indicators

Applications

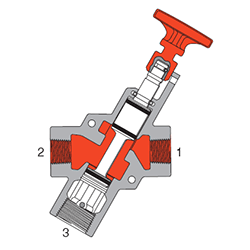

Lockout valves are installed in pneumatic drop legs, or individual pneumatic control lines. In accordance with OSHA procedures, lockout valves are used during maintenance and service procedures of pneumatically (air) operated equipment. Prior to servicing, the red handle is pressed inward, blocking pressure and relieving all downstream air pressure. A padlock is installed through the locking hasp, preventing accidental actuation during the maintenance procedure. Following maintenance, the padlock is removed and the red handle is pulled outward, returning air pressure to the system.

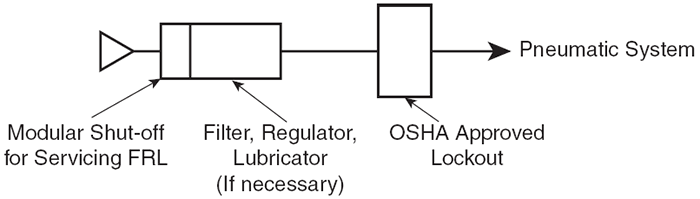

Placement of Lockout Device

Operation

Valve Closed

With a short inward push of the red handle, the flow of supply air is blocked from the outlet port. Downstream air flows from outlet to exhaust port. The valve must be padlocked while in this position during maintenance to prevent it from being inadvertently pulled outward and creating the potential for injury to people or machinery.

With a short inward push of the red handle, the flow of supply air is blocked from the outlet port. Downstream air flows from outlet to exhaust port. The valve must be padlocked while in this position during maintenance to prevent it from being inadvertently pulled outward and creating the potential for injury to people or machinery.

Valve Open

When the red handle is pulled out, supply air flows freely from inlet to outlet, and flow to the exhaust port is blocked. A detent keeps the handle in the open position. The handle is not designed to be locked in the open position so that the valve is always ready for shutoff.

When the red handle is pulled out, supply air flows freely from inlet to outlet, and flow to the exhaust port is blocked. A detent keeps the handle in the open position. The handle is not designed to be locked in the open position so that the valve is always ready for shutoff.

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise. The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors. To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

➤ Back to Top

✉ Email this Page

Also Available from mdi

|

TransairPipeSales.com is owned and operated by mdi, Manufacturers Distributor, Inc. mdi is an Authorized Parker Transair Piping System Distributor. Click Here to view the mdi Line Sheet. |

Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View

Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View Click For Larger View

Click For Larger View